Engineering Services

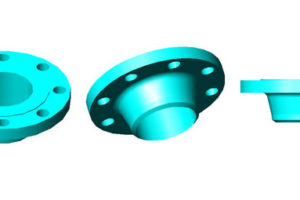

Our engineering services range from tool or mold design to finite element analysis of the molded parts. An experienced team of tooling engineering staff handles different mold types and takes into consideration various design characteristics, such as gate cutoff, cold manifold, plus rising islands.

Each mold is designed with emphasis on achieving perfect quality, maximizing production efficiencies, and controlling product cost. In addition to designing tools, we also have a fully equipped tool shop for maintenance and repair of molds. All molds undergo regular maintenance and inspection after every production run.

Our engineering staff also has the capability to design and fabricate machining fixtures to be used with our secondary services equipment. These fixtures act as workholding tools to assist the automated operation of our CNC drilling machines and machining centers. Besides tool and fixture design, engineering assistance is also given for metal-to-plastic conversions as well as new applications.

Engineering Capabilities

- Engineering Capabilities

-

Finite Element Analysis

Fixture Design

Tool DesignFirst Article Inspection/PPAP

MasterCAM Programming

- ISO Certification

-

ISO 9001:2015 Registered

- Production Runs

-

1 Piece to over 1,000,000 Parts Annually

- Quality Certifications

-

ISO 9001:2015 Registered

- Software Used

-

AutoCAD

SolidWorksMasterCAM

SpinFire

- Acceptable File Formats

-

DWG

DXF

GIFPDF

STEP

- Industries Served

-

Aerospace

Defense

Electrical

Medical

Food & BeverageHousewares

Lighting

Restaurant

Appliance

Park & Recreation